HYDRO TEST PUMPS

We continue to provide endless support in testing the powerful Hydro systems with the most effective and safest Hydro Testing machines. Explore PressureJet's wide range of safe and effective High-Pressure Hydro Testing Machines.

PressureJet anticipates market requirements based on demand trends and environmental changes, and then feeds back innovation to create new services. The Electric and Diesel engine-driven Hydro Testing Systems are one such piece of equipment with a compact design, low cost, and high efficiency.

Flow and Pressure Combinations

Flow rate: 12 LPM to 445 LPM

Pressure: 70 bar (1,000 PSI) to 1,400 bar (20,000 PSI)

PressureJet's contribution to Hydro Test Pumps

1. Hydrostatic Pressure Test Pump with pre-filling cum pressure building system.

2. A unique Automatic Hydro Test Controller that improves the safety and efficiency of your system.

Hydro Test Pump Applications

Custom System

-

What is hydrostatic pressure testing?Hydrostatic testing is a procedure that uses a hydrostatic testing pump to check equipment such as fire extinguisher cylinders, storage tanks, gas cylinders, and chemical pipelines. The equipment is inspected for leaks and the units' overall integrity is determined. The hydrostatic pump checks if the unit can safely hold the pressure it is rated for by measuring the rate of expansion of the tube under water pressure.

-

How does a hydrostatic pressure test work?Filling a component with liquid, usually water, using a high-pressure plunger pump until the pressure reaches a certain level is the first step in hydrostatic testing. A pressure larger than the equipment's designed operating pressure is applied and sustained for a certain length of time, during which the equipment is inspected for leaks.

-

For which application is high pressure hydrostatic testing (hydro test) required?High pressure hydrostatic test is mostly required in industry Boiler hydro test, Casting hydro test, Cylinder hydro test, Cross country pipeline hydro test, Hydraulic fittings hydro test, Jacket hydro test, Mandrill extraction from hoses & cables, Rubber hose pre filling & hydro test, Pipe hydro test and Burst test, Plumbing hydro test, Valve hydro test, Various industrial equipment hydro test, Vessel hydro test, Weld joints hydro test.

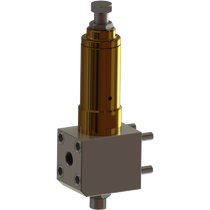

Hydro Test Pump Accessories

-

What is hydrostatic pressure testing?Hydrostatic testing is a procedure that uses a hydrostatic testing pump to check equipment such as fire extinguisher cylinders, storage tanks, gas cylinders, and chemical pipelines. The equipment is inspected for leaks and the units' overall integrity is determined. The hydrostatic pump checks if the unit can safely hold the pressure it is rated for by measuring the rate of expansion of the tube under water pressure.

-

How does a hydrostatic pressure test work?Filling a component with liquid, usually water, using a high-pressure plunger pump until the pressure reaches a certain level is the first step in hydrostatic testing. A pressure larger than the equipment's designed operating pressure is applied and sustained for a certain length of time, during which the equipment is inspected for leaks.

-

For which application is high pressure hydrostatic testing (hydro test) required?High pressure hydrostatic test is mostly required in industry Boiler hydro test, Casting hydro test, Cylinder hydro test, Cross country pipeline hydro test, Hydraulic fittings hydro test, Jacket hydro test, Mandrill extraction from hoses & cables, Rubber hose pre filling & hydro test, Pipe hydro test and Burst test, Plumbing hydro test, Valve hydro test, Various industrial equipment hydro test, Vessel hydro test, Weld joints hydro test.

Clients

What Our Clients Say

Performance Certificates

PressureJet Systems Pvt. Ltd. specialises in high pressure water jet pumps and systems. For more than 25 years, customers have come expecting high-quality products and services from the company. As a result, we surpass the standards set by other companies in the Indian subcontinent.

We manufacture the most comprehensive line of high-pressure triplex plunger pumps in the industry, with pressure ranging from 60 bar to 1400 bar. Product lines are designed to meet the needs of majority of customers across a wide range of industries and applications. We provide complete systems for a variety of applications, including high-pressure water jetting, hydro blasting, and hydrostatic pressure testing. We also offer high-pressure cleaning, sewer jetting, UHP fire fighting, and high-pressure water sand blasting systems.

As a company, we excel at providing high-quality products at low prices to our clients. Because quality assurance should lower product prices rather than increase them. To ensure the quality of our products, we have implemented stringent quality controls throughout the manufacturing, assembly, and testing processes.

No other brand can demonstrate how 257 precision-calibrated testing and measurement equipment are used to meticulously examine each component of your pump. If this is the case, ask how long does it take from raw material to completion.

Contrary to the majority of other manufacturers, we don't want you to simply take our word for it. Words barely scratch the surface of our capabilities at PressureJet. We are proud to have a team of engineers who deal with statistics and facts.

About PressureJet

25+

Years of Expertise

5000+

Globally Happy Customers

80%

In-House Manufacturing

90%

Parts Inspected on CMM

50+

Experienced

Engineers' Team

Contact

Head Office

21- 24, Panchratna Industrial Estate,

Near Oad Village, Paldi Kankaj, Pirana, Ahmedabad, Gujarat, 382427, India

Tel: +91 937-502-2359

Service

Tel: +91 823-803-1988

Get a quote: +91 937-502-2359